Know More! It will only take a minute

Agromax Boiler – Technical Overview & FAQs (click to expand)

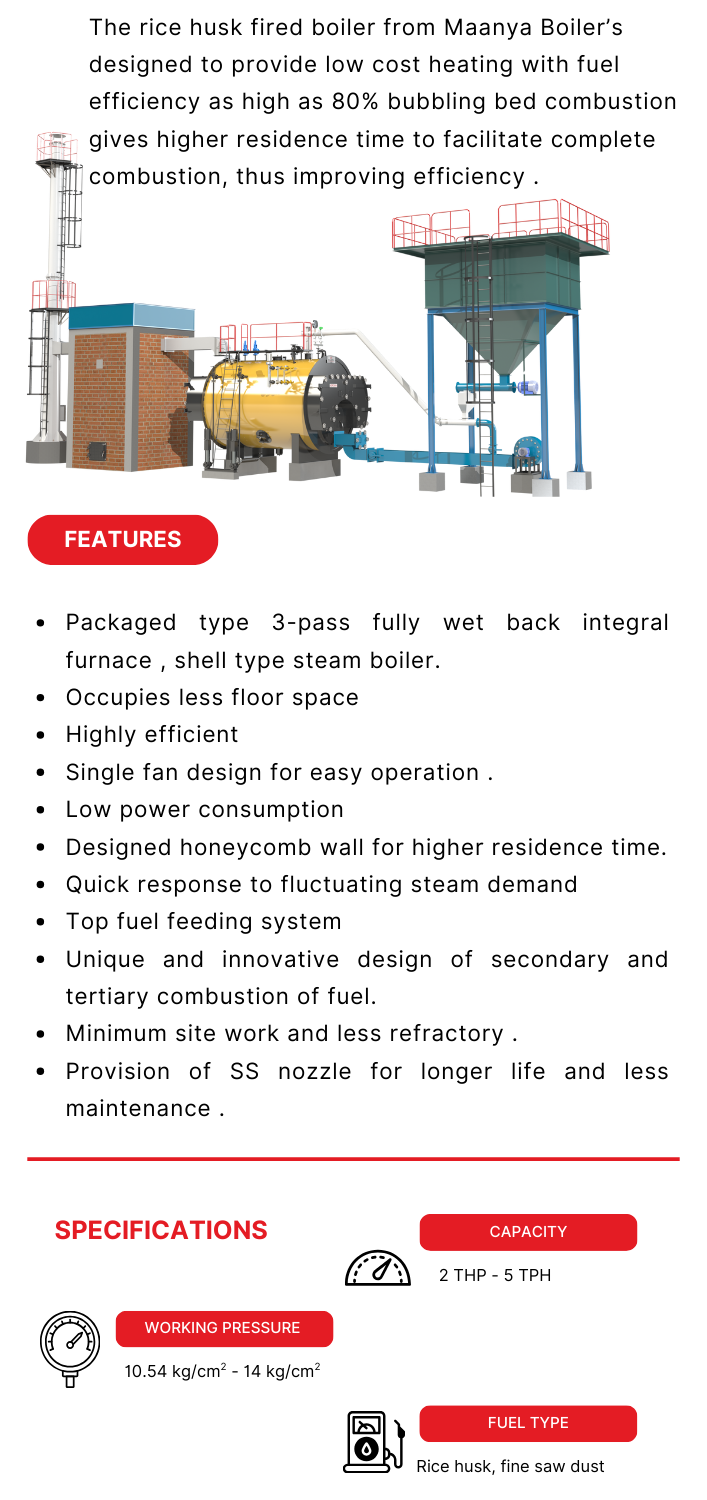

Agromax Boiler systems by Maanya Boilers are engineered for industries requiring high fuel flexibility, strong combustion efficiency and reliable steam generation across varied operating conditions.

Agromax Boiler – Key Features

The Agromax Boiler is designed to handle agro-waste, biomass fuels, husk and other solid fuels with stable performance. Its construction supports continuous-duty operation and efficient heat transfer for industrial applications.

The unit’s design integrates a well-balanced furnace, heat-absorbing surfaces and smooth draft movement to maintain stable combustion. The boiler layout ensures even flame distribution, minimized heat loss and predictable steam quality for daily process needs.

Industries select Agromax Boiler for its ability to run on multiple biomass fuels, making it suitable for sites with fluctuating fuel supply conditions. Its firing system and grate arrangement allow consistent burning even with variable moisture content.

- Optimized biomass combustion for agro-residue fuels

- Strong thermal efficiency for steady output

- Durable welded pressure components

- Low maintenance with easy access points

Agromax Boiler is suitable for textiles, food processing, chemical plants, rice mills, agro-industries and heating applications requiring steady, cost-effective steam generation. Optional automation features support smooth operation and improved safety.

Applications & Suitability

The unit’s flexibility with agricultural fuels makes it highly suitable for industries located near agro-production zones. It supports a wide range of industrial processes requiring medium to high steam output.

Routine checks include feedwater control, grate movement, combustion air settings and safety interlocks. These ensure the unit maintains reliability over extended duty cycles.

Related pages: Our Boiler Range · Request a Quote · About Maanya Boilers

Reference: MNRE – Renewable Energy

Agromax Boiler – FAQs

What fuels can the boiler operate on?

It supports a wide range of agro-waste and solid biomass fuels, making it suitable for locations with affordable fuel availability.

Which industries commonly use this model?

Industries like textiles, chemicals, rice mills, food processing, and agro-industries prefer this model for stable and cost-effective heating.

Does the boiler provide steady steam output?

Yes, it is designed for uniform heat transfer and consistent steam delivery suitable for continuous industrial usage.

Is after-sales support available?

Yes, Maanya Boilers provides commissioning, operator training, maintenance and spare-parts support for all Agromax units.

About Maanya Boilers – Additional Technical Overview

Maanya Boilers Pvt. Ltd. has established itself as a trusted manufacturer of industrial steam solutions, serving a wide range of sectors across India. The company emphasizes engineering precision, operational safety and long-term performance across all of its boiler models. Over the years, the organization has invested in research, fabrication upgrades and improved manufacturing techniques to meet modern industrial requirements.

The engineering team at Maanya Boilers works closely with clients to understand site conditions, production patterns and resource availability. This approach ensures that equipment recommendations align with real on-ground usage and long-term operational goals. A systematic evaluation process is used before finalizing specifications, which includes thermal calculations, material selection and pressure component sizing.

The company operates with strict quality standards, following recognized fabrication norms and multiple quality checkpoints throughout the manufacturing cycle. Every unit undergoes inspections, hydro tests and performance trials before dispatch, ensuring consistent delivery and reliability once installed at the client’s location. These procedures help reduce installation challenges and shorten commissioning timelines.

In addition to equipment supply, Maanya Boilers offers a complete service ecosystem that includes installation supervision, commissioning assistance and operator training. Dedicated service teams are available for periodic maintenance visits, troubleshooting support and spare-part planning. This comprehensive support structure helps industries maintain predictable steam output and minimize unexpected downtime.

The organization continues to expand its capabilities through technology partnerships, upgraded fabrication tools and greater attention to sustainability. With a focus on energy efficiency, emissions compliance and improved lifecycle performance, Maanya Boilers strives to deliver industrial solutions built for the future.

This section expands on the company’s background and engineering culture to meet recommended documentation standards while keeping the main page layout unchanged. It adds technical and corporate context relevant to industrial buyers and supports a more complete understanding of the company’s operations.