Rice Straw / Cane Trash / Mustard Bale Fired Multi-Fuel Boiler – Biomass Boiler

At Maanya Engineering Company, we are commited to providing innovative and sustainable energy solutions. With the rising concerns of climate change and envioronmental pollution, the shift towards renewable energy sources has become essential.

Our Rice Straw, Cane Trash and Mustard Bale Fired Multi Fuel Boiler is designed to utilize agricultural waste effectively, reducing reliance in fossil fuels.

Paddy Straw, Cane Trash, Bagasse and Mustard Bale are commonly discarded agricultural residues in India. Their open field burning releases harmful pollutants, contributing to severe air pollution and respiratory issues.

By using these biomass fuels in our advanced boiler systems, we offer a cleaner and more sustainable alternative, minimizing enviornmental impact while maximizing energy efficiency.

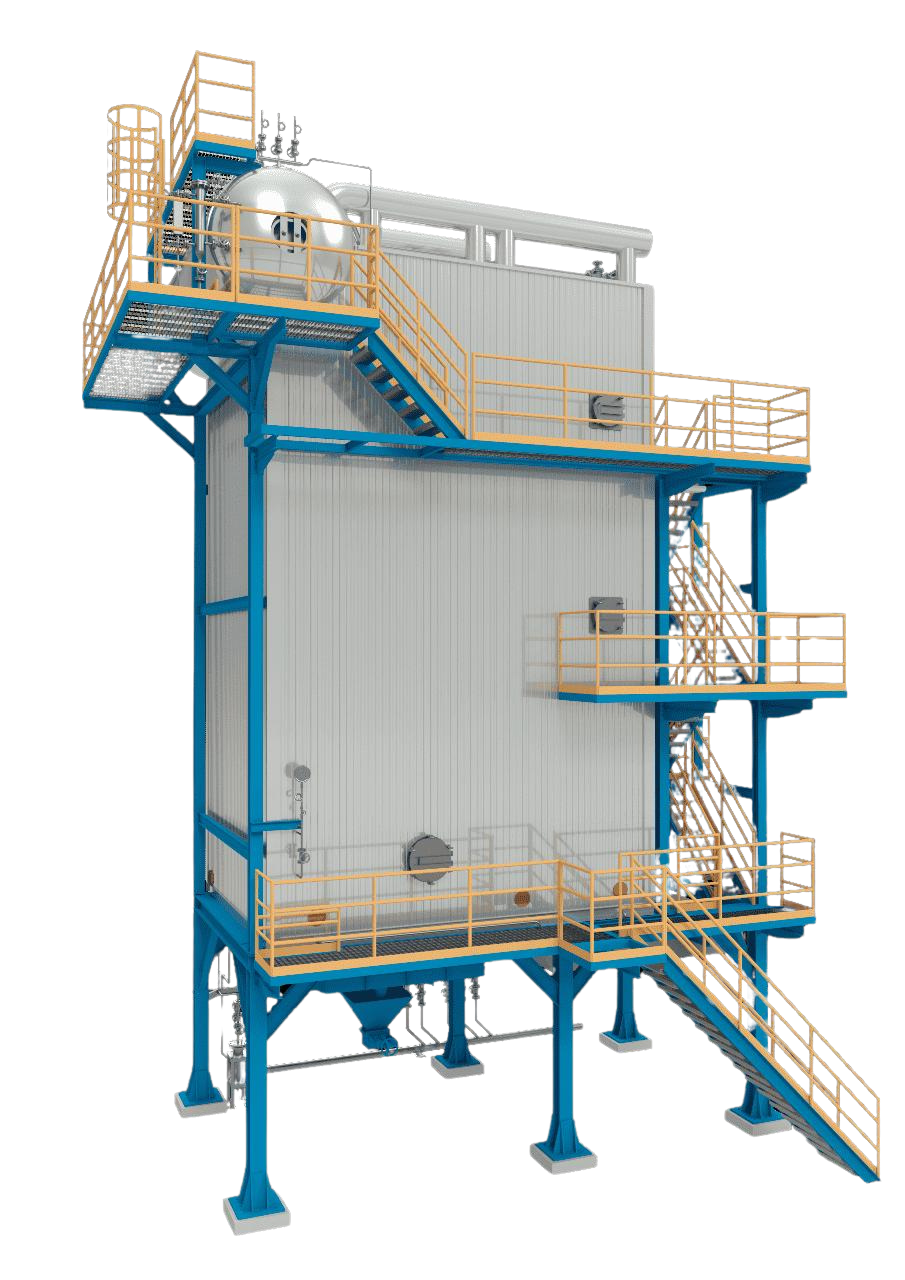

To address the challenge of handling these fuels effectively, Maanya Engineering Company has developed an advanced combustion system featuring a Pulsating Grate and Reciprocating Grate Boiler.

This technology ensures optimal fuel disintegration, improved combustion efficiency, and reduced emissions, making it an eco-friendly and cost effective solution for various industries.

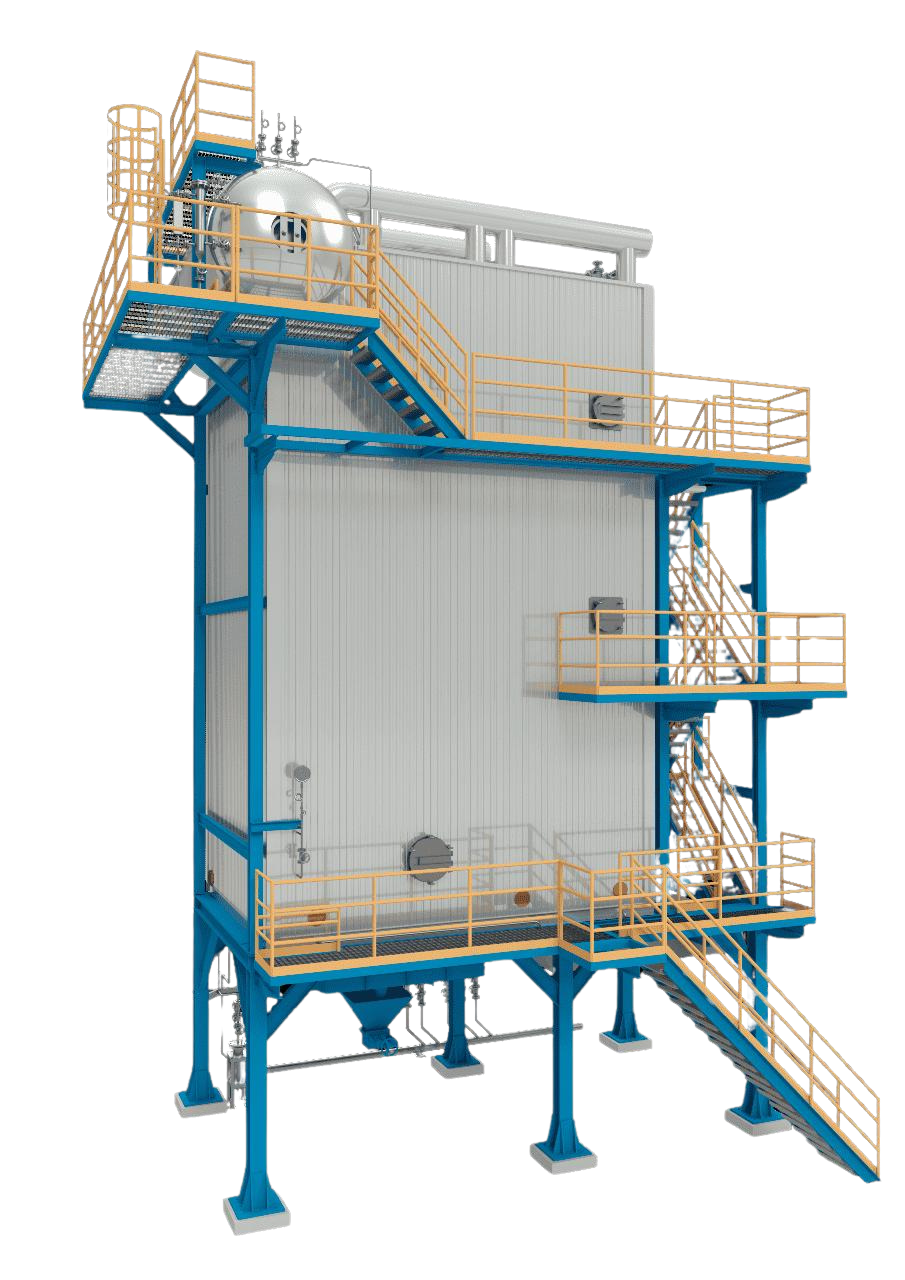

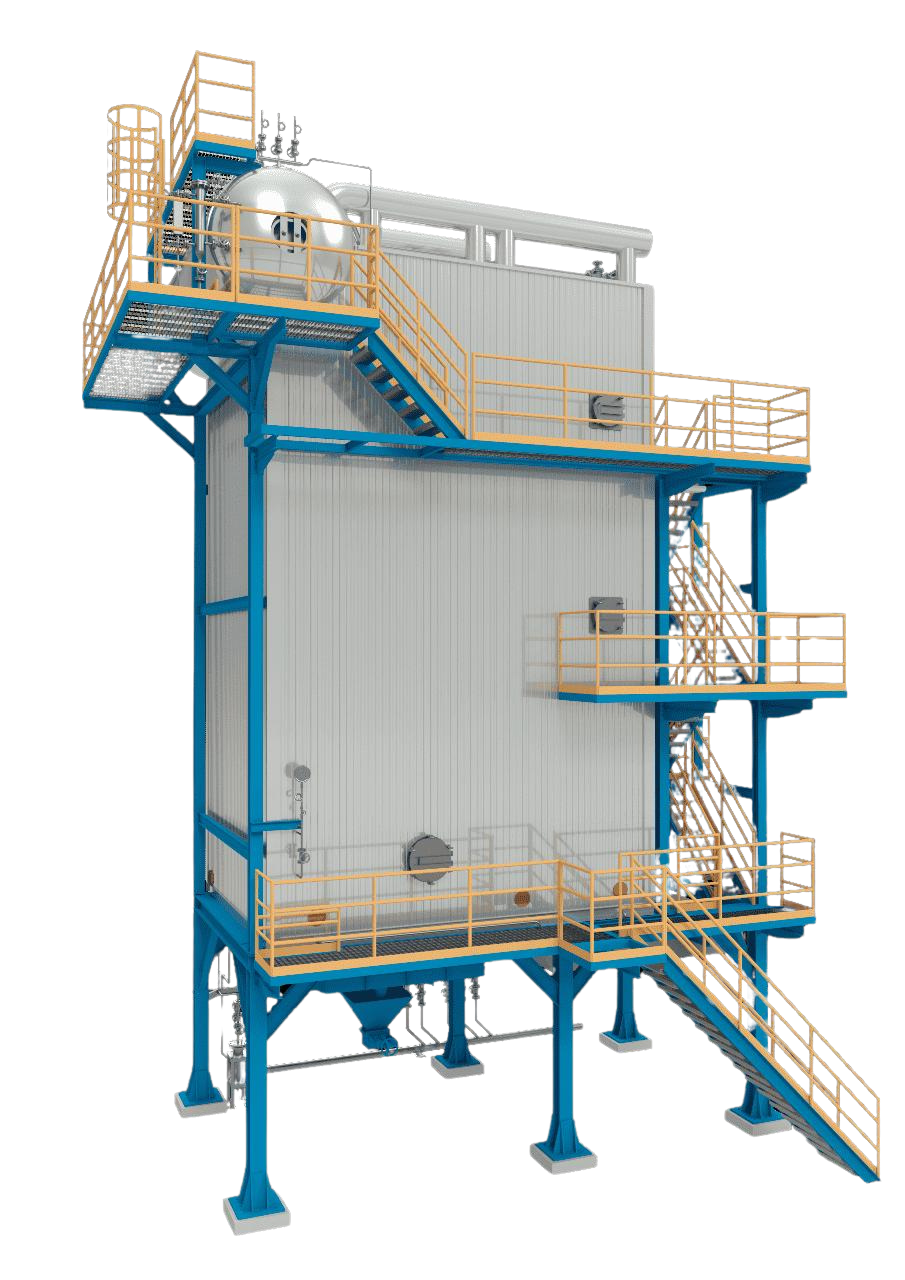

Reciprocating Grate

The Reciprocating Grate boiler is a high-efficiency biomass combustion system designed to handle various fuels while ensuring complete combustion, lower emissions and reduced maintenance. It is an ideal choice for industries seeking cost-effective and eco-friendly energy solutions.

Key Features

Three-Pass Water Wall Design – Enhances heat transfer and improves thermal efficiency

Multi Stage Air and Fuel Distribution– Ensures complete combustion with minimal unburn fuel. Optimum air to fuel ratio.

Large Fuel Bed Area – Increases fuel residence time, optimizing burning efficiency.

High-Pressure Secondary Air System – Improves turbulence and air-fuel mixing for better combustion.

Minimal Clinker Formation – Reduces maintenance and prevents operational disruptions.

Effective Heat Transfer – Water walls and convective surfaces boost energy output.

Key Benefits

High Efficiency & Fuel Flexibility – Supports biomass fuels like bagasse, rice husk, wood chips and municipal waste.

Lower Maintenance & Less Downtime – Robust design reduced wear, ensuring long-term reliability.

Reduced Ash Carryover – Cleaner operation with better ash management.

Eco-Friendly with Low Emissions – Optimized combustion lowers CO and Nox emissions.

Biomass Boiler:

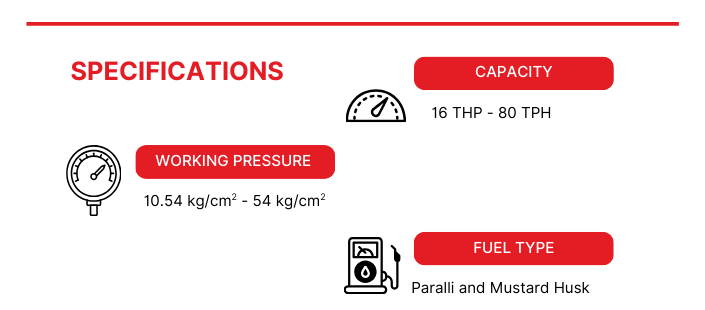

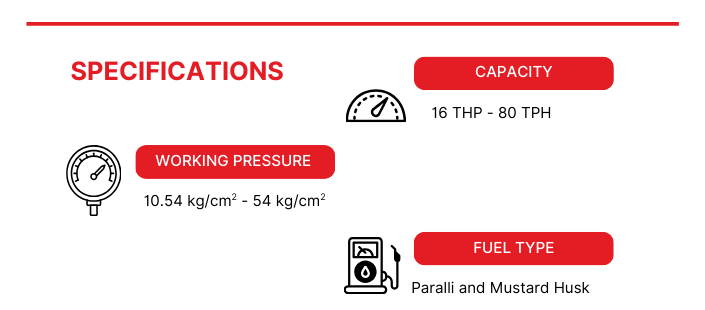

Hybrid Biomax Boiler

(Combination of Water cum Smoke tube boiler)

Salient Features of Hybrid Biomax Boiler with Reciprocating Grate :

Hybrid Design for High Efficiency

Combines water tube (for rapid heat transfer) and smoke tube (for better heat retention) to achieve efficiency of 80-85%.

Reciprocating Grate System

– Supports moisture content up to 50%, ensuring uniform fuel combustion and reducing clinker formation.

– Can handle fuel particle sizes ranging from 10 mm to 600 mm.

Multi-Fuel Capability

– Compatible with biomass fuels such as rice straw, cane trash, mustard bale, wood chips, and husk.

– Fuel feeding rate: 500-5000 kg/hr, depending on MCR rating of boiler.

Low Emission Technology

Equipped with multi-cyclone dust collectors and wet scrubbers for emission control.

Automated Fuel Feeding & Ash Handling

– Continuous screw or pneumatic feeding system ensures optimized fuel input.

– Automatic ash removal system with less than 5% unburnt carbon in ash for improved efficiency.

Robust & Durable Construction

Designed to withstand pressure ratings of 10-67 kg/cm² and temperature up to 450°C.

WATERTUBE BIOMAx BOILER

Salient Features of Water Tube Boiler with Reciprocating Grate :

High Thermal Efficiency & Rapid Heat Transfer

Water tube design ensures faster heat absorption, achieving efficiencies of 85-90% with optimized fuel combustion.

Reciprocating Grate System for Biomass Fuels

– Efficiently handles high-moisture biomass fuels like rice straw, cane trash, mustard bale, wood chips, and bagasse.

– Supports moisture content up to 55% and fuel sizes from 10 mm to 150 mm.

High-Pressure & High-Temperature Operation

Can operate at pressures from 10 to 100 kg/cm² and temperatures up to 540°C, making it suitable for industrial power generation.

Multi-Fuel Flexibility

Designed to burn a variety of solid fuels, including biomass, coal, and agro-waste, ensuring adaptability to fuel availability.

Optimized Steam Generation

Provides steady, dry, and superheated steam with high steam-to-fuel ratio for efficient power and process heating.

Advanced Ash & Emission Control System

– Reciprocating grate allows continuous ash discharge, minimizing clinker formation and reducing unburnt carbon to <3%.

– Equipped with multi-cyclone dust collectors and wet scrubbers for cleaner operation.

Know More! It will only take a minute

Biomass Boiler – Technical Overview & FAQs (click to expand)

Biomass Boiler systems by Maanya Boilers are designed to utilize rice straw, cane trash, mustard bale and other agro-residues as sustainable fuel alternatives while ensuring efficient steam generation for industrial applications.

Biomass Boiler – Technical Overview

The Biomass Boiler offered by Maanya Boilers is engineered for high combustion efficiency using advanced grate technologies such as reciprocating and pulsating grates. These systems support agricultural waste fuels with varying moisture and size characteristics, ensuring cleaner combustion and reduced emissions.

The boiler is capable of firing paddy straw, cane trash, bagasse, mustard bale and other biomass fuels that are typically difficult to burn in conventional systems. Specialized fuel-feeding arrangements and multi-stage air distribution help maintain stable firing conditions even for fuels with high moisture content.

Reciprocating grate technology provides controlled fuel movement, longer residence time, reduced clinker formation and uniform combustion. This results in higher thermal efficiency, low maintenance and lower unburnt carbon levels in ash discharge.

The hybrid and water-tube variants mentioned on the page offer rapid heat transfer, high-pressure operation and the ability to handle fuel sizes ranging from fine particles to large biomass bales. Multi-cyclone collectors and wet scrubbers help maintain compliance with emission norms.

- Efficient burning of high-moisture agricultural residues

- Multi-fuel capability including straw, bagasse & agro-waste

- Reduced emissions due to optimized air–fuel mixing

- Adaptable grate systems for diverse biomass fuels

Industrial Applications

Biomass Boiler is widely used in textiles, food processing, chemical industries, rice mills, FMCG, plywood plants and agro-industries where sustainable steam generation and cost-effective fuel options are important. Biomass firing significantly lowers fuel expenditure and reduces dependence on fossil fuels.

Routine operational focus includes fuel preparation, combustion air management, ash handling and monitoring of emissions equipment such as multi-cyclone dust collectors or wet scrubbers.

Related: Our Boiler Range · Request a Quote · About Maanya Boilers

Reference: MNRE – Renewable Energy

Biomass Boiler – FAQs

Which fuels can be used in the Biomass boiler?

Rice straw, cane trash, mustard bale, bagasse, rice husk, wood chips and other agro-residues can be used, depending on fuel availability at site in the Biomass boiler.

What makes the reciprocating grate useful?

Biomass boiler offers uniform fuel spreading, longer residence time, reduced clinker formation and better combustion even with high-moisture biomass fuels.

Can Biomass Boiler handle high-moisture?

Yes, the grate systems and multi-stage air supply allow combustion of fuels with moisture content up to 50–55% depending on the model.

Is emission control supported in Biomass boiler?

Yes, multi-cyclone dust collectors and wet scrubbers are used to maintain compliance with air-quality norms.

Which industries benefit from using biomass boiler?

Industries aiming to reduce fuel costs and switch to renewable energy—such as rice mills, textiles, chemicals, FMCG and food processing—benefit significantly.

About Maanya Boilers – Additional Technical Overview

Maanya Boilers Pvt. Ltd. has established itself as a trusted manufacturer of industrial steam solutions, serving a wide range of sectors across India. The company emphasizes engineering precision, operational safety and long-term performance across all of its boiler models. Over the years, the organization has invested in research, fabrication upgrades and improved manufacturing techniques to meet modern industrial requirements.

The engineering team at Maanya Boilers works closely with clients to understand site conditions, production patterns and resource availability. This approach ensures that equipment recommendations align with real on-ground usage and long-term operational goals. A systematic evaluation process is used before finalizing specifications, which includes thermal calculations, material selection and pressure component sizing.

The company operates with strict quality standards, following recognized fabrication norms and multiple quality checkpoints throughout the manufacturing cycle. Every unit undergoes inspections, hydro tests and performance trials before dispatch, ensuring consistent delivery and reliability once installed at the client’s location. These procedures help reduce installation challenges and shorten commissioning timelines.

In addition to equipment supply, Maanya Boilers offers a complete service ecosystem that includes installation supervision, commissioning assistance and operator training. Dedicated service teams are available for periodic maintenance visits, troubleshooting support and spare-part planning. This comprehensive support structure helps industries maintain predictable steam output and minimize unexpected downtime.

The organization continues to expand its capabilities through technology partnerships, upgraded fabrication tools and greater attention to sustainability. With a focus on energy efficiency, emissions compliance and improved lifecycle performance, Maanya Boilers strives to deliver industrial solutions built for the future.

This section expands on the company’s background and engineering culture to meet recommended documentation standards while keeping the main page layout unchanged. It adds technical and corporate context relevant to industrial buyers and supports a more complete understanding of the company’s operations.